Exportation

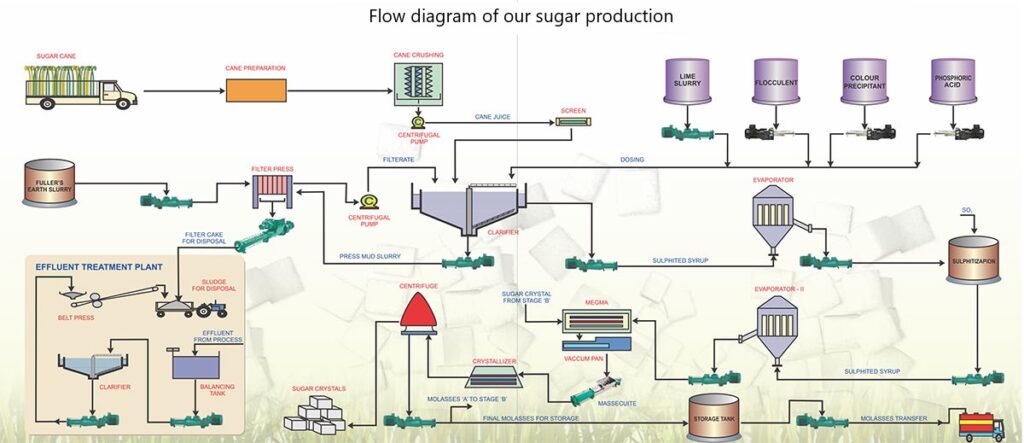

The production of sugar has advanced rapidly in the modern era, and slave labor has been replaced by technology. For many years, Brazil has led the way in the development of the sugar industry. It has sequenced the genome of sugar cane, created over 100 strains of the crop, and developed methods for milling and refining the crop that are so sophisticated that refineries and mills can often sell excess energy back to the national grid instead of needing to pay for electricity to run their operations.

VHP raw sugar, a raw sugar product with a minimum sucrose concentration of 99.4%, was also created in Brazil. Before VHP raw sugar was developed, raw cane juice would be cooked or evaporated until a dark brown, contaminant-filled natural sugar product was combined with molasses. It took a lot of processing to get this raw sugar into the glistening white ICUMSA 45 sugar, which is now the preferred sweetener in the majority of the developed world.

Raw cane juice is heated to a boiling point where the concentration is high enough to generate sucrose crystals in order to create VHP sugar. After letting the juice cool until crystals start to form, centrifuging is used to separate the solution and the crystals. The centrifugal process separates the crystals from the molasses, the remaining liquid content.

We export in bulk, break bulk, and containerized forms.

Vessels:

Sugar in containers 20 Icumsa 45 – 100 – 150 Max. 26 m/tons package: Polybags 50 kilos 520 polybags per unit

Sugar Icumsa 45 – 100 and 150

In Break Bulk vessel

Package: polybags 50 kilos

Vessel Qty:

12.500 m/tons

25.000 m/tons

50.000 m/tons

** N.B – Prices C&F or CIF depending on quantity and destination. **

Procedure:

- Buyer issues ICPO and BCL (ICPO endorsed by bank officer)

- Seller approves ICPO and sends the Draft Contract

- Buyer / Seller sign the Contract

- Buyer opens non-operative SBLC or MT 103 to seller bank

- Seller issues POP to turn operative the financial instrument

- Shipments start as per contract terms.

Our Methods & Technology for Manufacturing Sugar